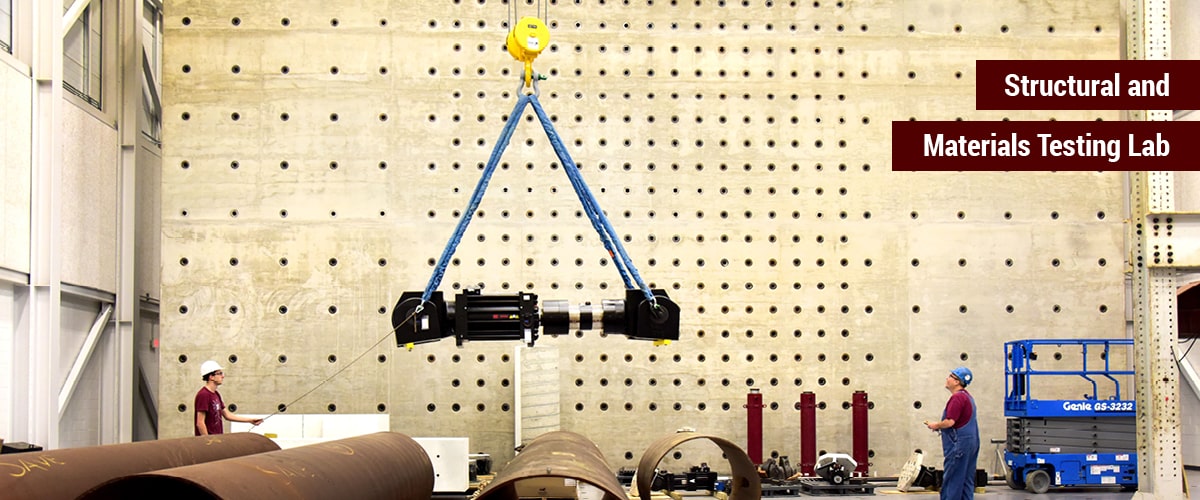

Materials Test Lab: Making Certain Top Quality and Efficiency

Wiki Article

Cutting-Edge Product Testing Lab: Accelerating Innovation With Accuracy

Are you trying to find an innovative material screening laboratory that can increase your innovation with accuracy? Look no even more. Our cutting edge center is geared up with advanced screening tools and makes use of cutting-edge testing techniques. With our precision dimensions and analysis, we can assist you accelerate your materials study. Experience the power of cutting-edge innovation in product screening and take your development to brand-new elevations.Advanced Screening Tools

You ought to look into our advanced testing equipment, it's modern and will certainly assist you accelerate innovation. Our sophisticated research laboratory is geared up with the most current innovation to guarantee accurate and precise testing of products. With our advanced devices, you can expect dependable outcomes that will drive your technology ahead.Among the vital pieces of devices in our lab is the modern global screening maker. This equipment is capable of performing a variety of examinations, such as compression, flexural, and tensile tests. With its high capability and advanced control system, you can with confidence check the toughness and toughness of your materials.

In enhancement to the global testing maker, we also have actually advanced spectroscopy equipment. This tools enables you to examine the chemical structure of your materials with excellent precision. By comprehending the make-up of your products, you can make enlightened choices regarding their efficiency and suitability for your certain applications.

Furthermore, our laboratory is equipped with innovative microscopy tools. This enables you to take a look at the microstructure of your materials thoroughly. By studying the microstructure, you can acquire understandings into the material's homes and potential areas for enhancement.

Cutting-edge Checking Techniques

One of the approaches we utilize is non-destructive testing, which allows us to evaluate the honesty of products without triggering any kind of damage. By making use of sophisticated imaging modern technologies such as ultrasonic testing and X-ray evaluation, we can take a look at the inner structure of products and recognize any kind of issues or flaws. This technique not just saves time and sources yet likewise ensures that the product stays undamaged for more testing or use.

Our laboratory is devoted to pressing the boundaries of product screening by employing these cutting-edge approaches. With greater precision and efficiency, we can offer our customers with dependable data and insights that drive innovation and boost item growth procedures. Depend on us to supply specific and trustworthy product testing results that will move your jobs to brand-new elevations.

Accuracy Dimensions and Analysis

One of the methods we're utilizing is non-destructive screening, which permits us to examine products without triggering any damages. With accuracy measurements and evaluation, we can explore the structure and buildings of numerous materials, enabling us to enhance their performance and improve development. By using sophisticated technologies, such as X-ray imaging, ultrasonic screening, and infrared thermography, we can obtain precise and comprehensive details about the internal framework and honesty of materials without changing their physical or chemical residential properties.With non-destructive screening, we can recognize any type of flaws, flaws, or problems that may exist within a material, ensuring its reliability and security. This technique enables us to detect surprise cracks, gaps, or powerlessness in a non-invasive manner, saving time and resources while mitigating potential risks. By pinpointing these problems at an early stage, we can proactively address them, avoiding costly failures or mishaps in the future.

In addition to spotting flaws, precision dimensions and analysis likewise enable us to review the efficiency and quality of materials. We can determine important characteristics such as hardness, strength, elasticity, and rust resistance, offering valuable insights for product selection and layout optimization. By understanding these residential properties, we can develop new products with improved performance and durability, pressing the borders of technology.

Accelerating Products Study

By employing non-destructive screening techniques, we have the ability to swiftly examine and assess various products, boosting the rate and efficiency of our products research study. These non-destructive testing techniques enable us to take a look at the properties of materials without triggering any kind look at this now of damage, conserving time and resources in the process. With techniques such as ultrasonic testing, radiography, and magnetic particle evaluation, we can identify the internal structure, flaws, and flaws of materials accurately Web Site and quickly.The advantage of non-destructive screening is that it allows us to collect useful data while preserving the stability of the products being studied. We can examine the top quality, reliability, and performance of different materials without endangering their capability. This is especially essential when dealing with costly or unusual samples, as harmful testing would certainly bring about their destruction and potential waste.

In enhancement to saving time and resources, non-destructive screening also improves the security of our study activities. By preventing the need to literally alter or break down products, we lessen the threat of accidents or mishaps during screening. This ensures a controlled and secure setting for our professionals and scientists.

Cutting-Edge Innovation in Material Screening

Utilizing cutting edge technology, we can swiftly and accurately assess the residential or commercial properties of different materials. With our advanced equipment and strategies, you can conserve time and sources in the product testing procedure - materials test lab. Our innovative machines enable for exact dimensions and evaluation, giving you a comprehensive understanding of the material's strength, toughness, and other key featuresThink of having the ability to identify the exact composition of a product within minutes, as opposed to waiting days or perhaps weeks for traditional screening techniques. Our technology allows you to do just that. By making use of non-destructive testing approaches, we can analyze the internal framework of materials without triggering any damages, ensuring that the honesty of the samples is maintained.

Additionally, our tools offers real-time information, allowing you to make enlightened decisions swiftly. You can assess the efficiency of various materials and recognize any weaknesses or locations for improvement. This rate and precision not only enhance the screening procedure however likewise drive advancement by allowing you to iterate and refine materials more successfully.

Final Thought

You have actually simply discovered the world of a sophisticated product testing lab, where development is increased with precision. By making use of innovative testing tools and cutting-edge techniques, this research laboratory is at the center of materials study. With its accuracy dimensions and evaluation, it permits a deeper understanding of product properties. By accepting innovative technology, this research laboratory remains to push the borders of what is possible in material screening. So, whether you're a researcher, designer, or merely curious regarding the world of materials, this laboratory is a hub of exciting explorations.One of the approaches we're making use of is non-destructive screening, which permits us to examine products without creating any damages.By employing non-destructive testing approaches, we're able to promptly review and evaluate numerous materials, improving the rate and effectiveness of our materials research study. These non-destructive screening approaches enable us to examine the residential or commercial properties of materials without creating any damages, saving time and resources in the process.You've simply checked out the globe of a sophisticated material testing visit this site laboratory, where technology is sped up with accuracy. By making use of sophisticated testing tools and ingenious methods, this laboratory is at the leading edge of materials study.

Report this wiki page